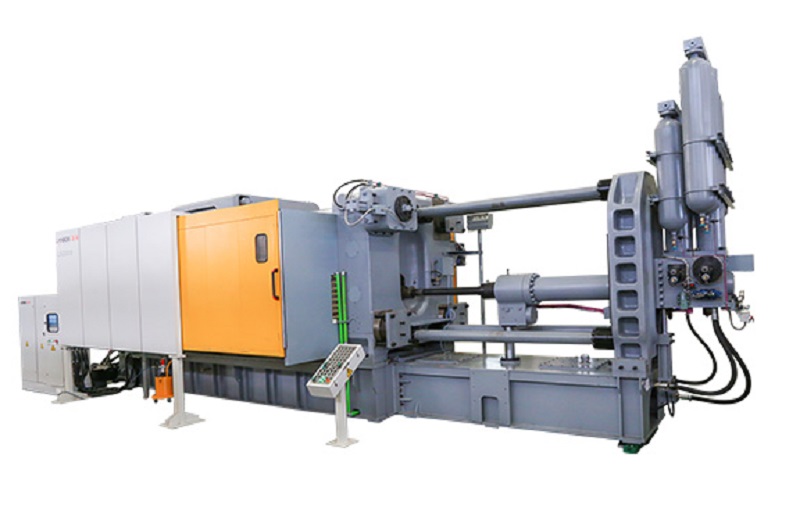

Die Casting Machine

Die-casting defects

(1) AIR POROSITY

MAINCAUSE:This defect is caused by trapped air in the casting which can come from several sources. It can be caused by poor shot end control, poor venting and overflow function or bad gating and runner design.

(2) SHRINKAGE POROSITY

MAIN CAUSES: This defect is caused by metal reducing its volume during solidification and an inability to feed shrinkage with more metal before solidification. Hot spots can also cause shrinkage porosity to be concentrated in a specific zone. See ‘sink’

(3) SHORT FILL

MAIN CAUSE:Metal is frozen before the cavity is filled or by insufficient metal being ladled.

1、 Metalcan cool down too much in the shot sleeve. FIRST STAGE VELOCITY TOO LOW;

2、 Somepart of the die may be too cold. POOR GATING&RUNNER DESIGN;

(4) COLD SHUT

MAINCAUSE:Metal is frozenwhen two metal fronts join.

Metal may be losing too much heat in the runnerand cavity.

(5) SCALING

MAIN CAUSE:Layers of metal and oxidescan be created by poor shot end control and /or bad gate and runner design.

(6) BLISTER

MAIN CAUSE:Trapped gases are in thecasting when the die is opened when the casting is still weak. This allows thecompressed gas to expend and cause a blister.

(7) FLASH

MAINCAUSE:Metal pressure istoo high upon the projected surface area (facing the platens ) of the castingat the end of cavity fill. This creates a force across the parting line whichis too great for the clamping force of the machine. The die is then forcedapart which allows metal escape.

(8) COLD FLAKES

MAINCAUSE:Metal is allowedto cool too much in the shot sleeve. The solid particles are then injected intothe cavity. These flakes are often clearly visible on the surface of thecasting with the naked eye.

(9) SHOT LUBE STAIN

MAIN CAUSE:This defectoccurs when too much shot (tip) lube is used.

(10) DRAG MARKS

MAINCAUSE:Insufficientdraft or an undercut causing a casting to be damaged on the surface when it isejected. This effect may be reduced by changing the temperature at which thecasting is ejected. Poor surface finish of the die can be another cause.

(11) HOT TEARING/CRACKING

MAINCAUSE:This defect iscaused by metal shrinking during solidification while under tension. At thelast place to solidify a tear or crack develops which can be seen at thesurface.

(12) HOT SHORTNESS

MAIN CAUSE:The composition of the alloycauses the metal to be too weak at high temperatures (after solidification ).This then can cause cracks in the surface of the casting to appear in regionsof high stress when the casting is cooling (and contracting ). NOTE: Thisdefect can occur in conjunction with hot cracking.

(13) SINK

MAIN CAUSE:A sink is caused by ashrinkage cavity being near the surface of the casting. This causes the surfaceof the casting to collapse into the cavity as solidification occurs. Sinks arecaused be the same things as shrinkage porosity as well as very poor thermalcontrol of the die because hot spots are required for sinks to form.

(14) EXPLODED METAL

MAINCAUSE:A combination ofporosity and the casting being ejected before it has solidified completely.This allows the trapped gases to burst out of the casting along with anyunsolidified metal.

(15) WARPAGE

MAINCAUSE:A casting candeform after ejection during the time it is cooling down to room temperature.The root cause can sometimes be the casting geometry or the alloyspecification. Warping can be minimized by ejecting at a lower temperature.Uneven die temperature is a major cause of this type of defect.

(16)SOLDERING

MAIN CAUSE: Chemical attack and bonding ofaluminium to die steel. This causes aluminium to be torn away from the castingduring ejection soldering can be reduced by a change in alloy and/or areduction in die/metal temperature.

(17)HEAT CHECKING

MAIN CAUSES: This defect is caused by thesurface of the tool steel continually expanding &contracting during use.Excessively cold dies &die flexing accelerate this effect.

(18)LEAKER

MAIN CAUSES: Causes of leaks in castingswhere pressure tightness is required can be oxide folds and/or inclusionsand/or porosity in conjunction with a surface defect which completes the pathfor a leak. A close analysis of the leaking area may reveal which of the manycauses is causing the leak.

(19)DISCOLOURED SURFACE

MAIN CAUSES: Oxide films (dross) and/orresidues in the cavity and/or particles in the metal and/or excess die lube cancause the surface to be discoloured. Also it can be caused by a part of the diebeing too cold causing the casting to have darker regions or ‘smears’ on thesurface.

(20)BREAK OUT

MAIN CAUSE: Metal flakes(cold flakes) whichget caught in the gate during cavity fill can break out unevenly when thecasting is trimmed.

(21)INCLUSIONS

MAIN CAUSES: The main causes of this type ofdefect are dirty/contaminated metal and/or poor melt banding practice.

(22)EJECTOR DAMAGE

MAIN CAUSE: In broad terms, it can bedefined as excessive pressure on the casting surface by the ejector pin(s)during ejection.

(23)EROSION/CAVITATION

MAIN CAUSES: Erosion is caused by directmolten metal impingment on die steel. Cavitation type erosion is caused byturbulence which causes low pressure regions in the flowing metal. These lowpressure regions cause voids to form which can collapse at the die surface&cause erosion.

(24)CRACKED CASTING

MAIN CAUSES: A crack in the casting can becaused by mechanical damage when the die is opened or when the casting isejected. This classification excludes HOT CRACKING &cracking at the surfacedue to SHRINKAGE POROSITY. Also, this definition excludes HOT SHORTNESS.

The common production problem and analysis of die castingmoulds

molten metal splash cause reason when die casting

1. cover half closing imprecision, have big gap

2. mould claming force not enough

3. die casting machine is flexible ,coverhalf mounting plate not parallel

4. Support span is large pressshoot pressure bring about the cleading deformation ,and engender spoutingmolden metal .

method of adjustment

1)reinstall the mould

2)increase the mould clamping force

3)adjust the die-castingmachine,ensure the moulding plate of cover half and moving die maintain nutualparallel

4)Add support plate on the movable mold,increase the stiffiness of the cleading

the factors influencing the workinglife of the pressure nozzle jet ,main factors :

1. the material and quality of the nozzlejet

2. the fit clearence of the press chargingbarrel and jet nozzle

3. the concentricity of the mould andcharging barrel

4. cooling problem

5. Selectand use the superior nozzle jet lube.

© Copyright: 2025 Lanson Precision Intelligence Equipment Technology Co., Ltd All Rights Reserved.