Plastic Injection Moulding Machine

Lanson 3D injection molding machine video

Lanson has scored the first companies by being the first at mass production for the single-cylinder plastic injection molding machines amount industry peers

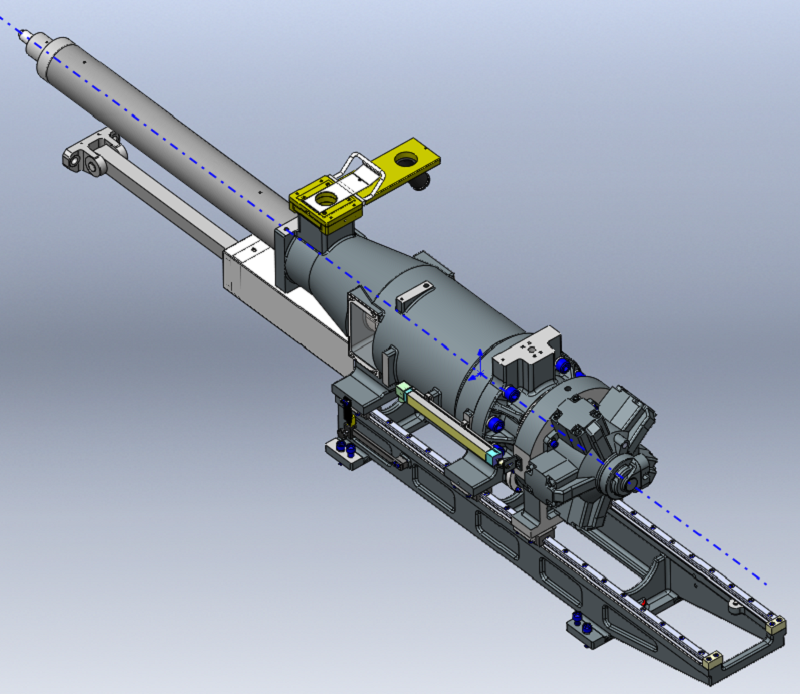

GT3 series plastic injection molding machine equipped with advanced single injection cylinder design, which is self-innovated and patented by Lanson. It features precision, fast response, high efficiency and energy saving. 27 patented design in this Series.

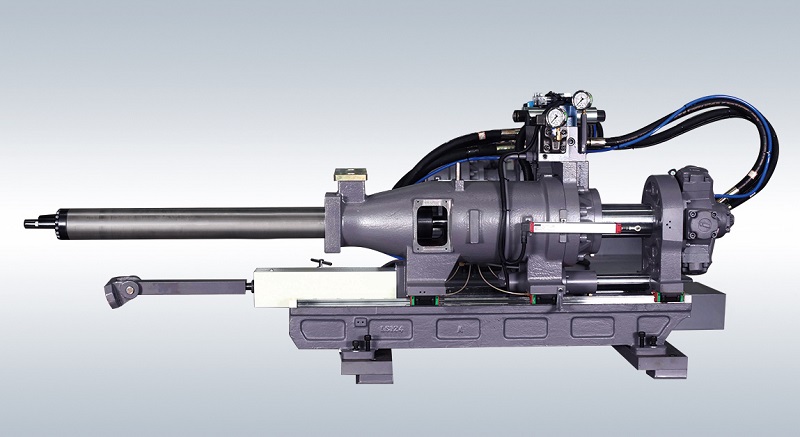

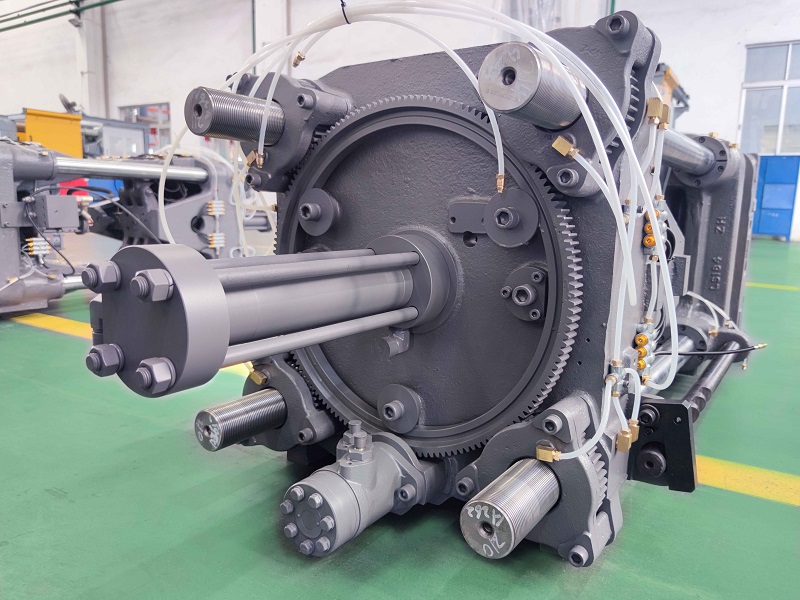

Single Injection Cylinder

Co-axial with screw & plasticizing motor, increase the injection pressure and speed. Have a fast and accurate injection performance. A new single cylinder injection system with more efficient injection performance, more compact design, higher injection pressure, for more sophisticated injection product. This special Injection unit front plate makes better concentric for screw and nozzle.

Low friction hydraulic design, minimize the injection resistance, fast response, ultra speed, more energy saving.

There is a window for monitoring screw rotation

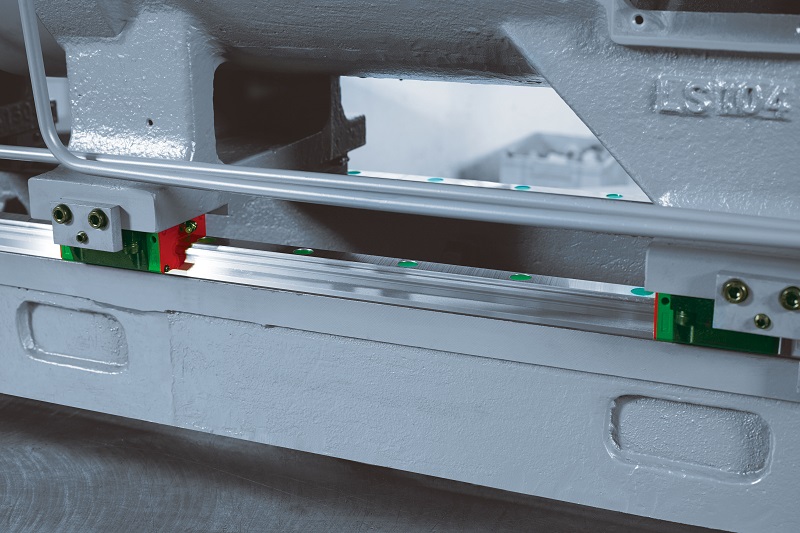

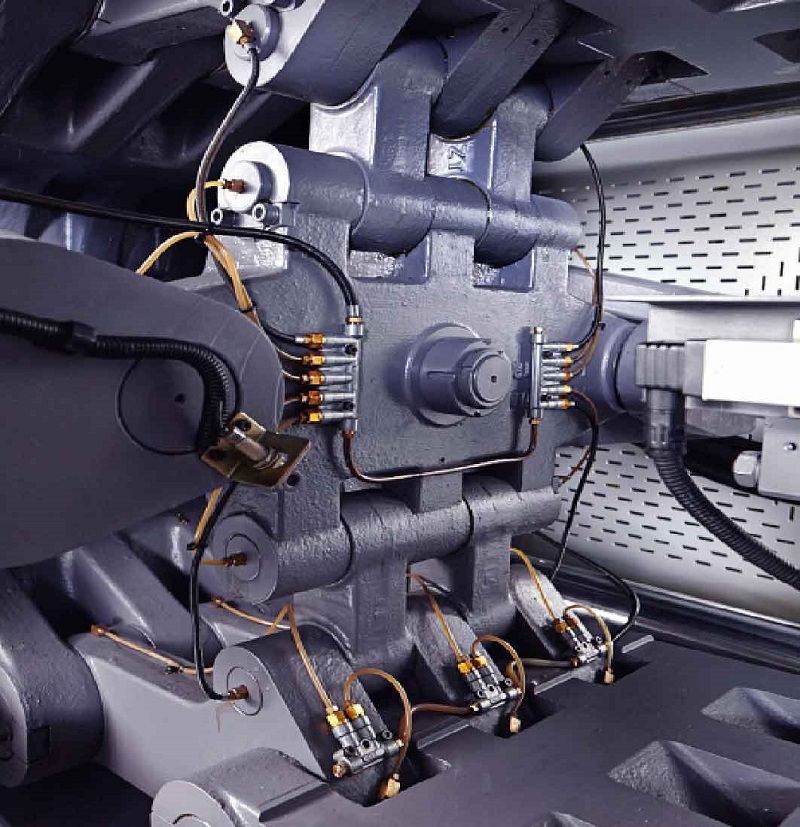

Injection unit linear guide way

Accurate, low friction, fast response, good repeat-ability and energy saving.

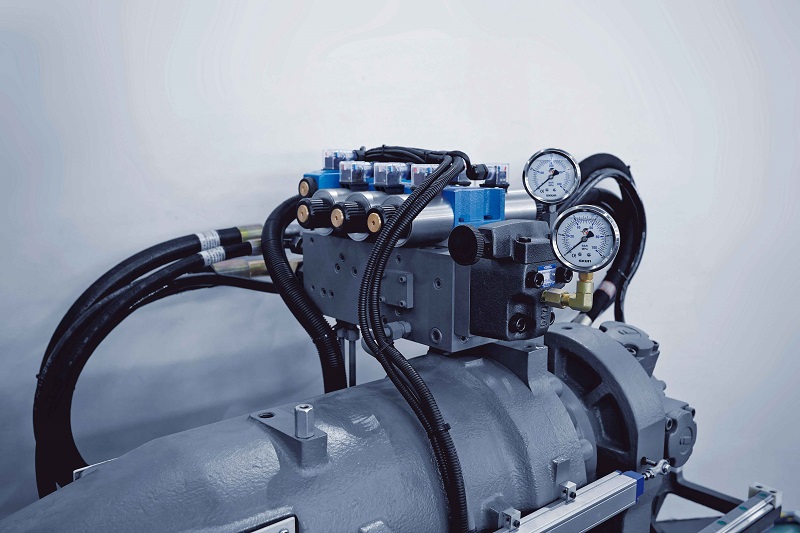

Injection action connect with control valve rigidity

Effective decrease fluid fluctuation and increase injection precision

Explostionproof chain

Protect from explosion of hydraulic oil hose to hurt people

Professional cable connection

A newly upgraded optional screw and barrel

Optional diversified screws and barrels, newly upgraded screw and barrel improve the quality of color mixing and plasticizing speed, high precision, wear-resisting, wider applicability.

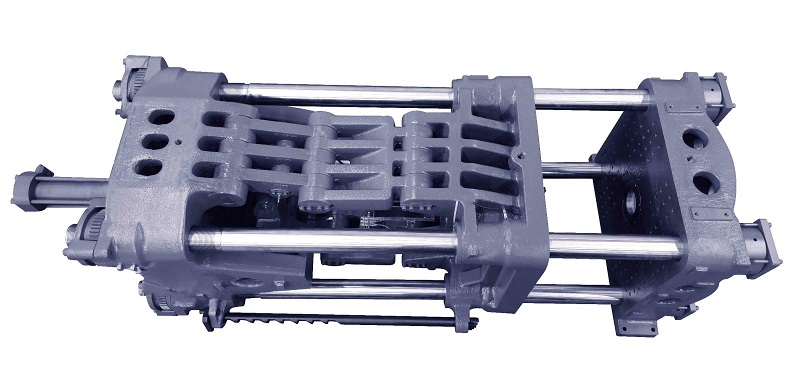

Widen toggle hinges with longer service life

In order to increase the service life of hinge pin and steel jacket, we increase the number of hinge pins and steel jackets shearing surface.

Increased and Widened hinge ears

Stress received by molding platen is dispersed equally and avoid stress concentration by widen hinges on moving platen.

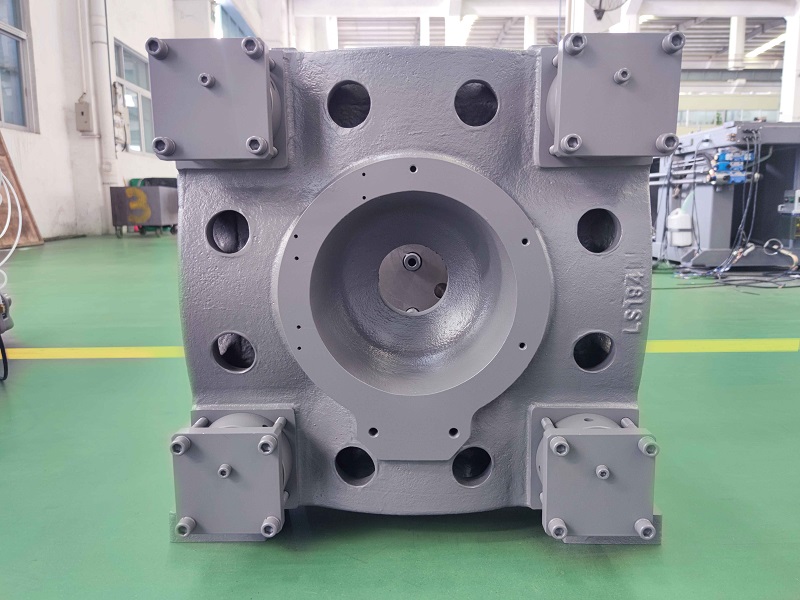

Optimized fixed platen design

The fixed platen employed the patented design of our company “arched molding platen”, stress will disperse out. As a result of no stress concentration, service life of molding platen is extended . Optimized strengthen moving platen with better stress uniform and longer service life. Distortion of platen is strictly controlled by finite element analysis.

Reinforced Crosshead

The crosshead has wide and thick structure, strong structural rigidity and long service life

Accurate and time saving gear mold adjusting system

Employed accurate gear mold adjusting device, the mold adjusting action is smooth and fast. It can also save the mold setting time after mould changing.

Diversification professional control system

Advanced control system, which function is control sensitive and precise, intelligent optimization mold open and close movement curve, manufacturing management, fault diagnosis and so on.

Using level pad during the installation period

Make sure the machine level is in the perfect situation

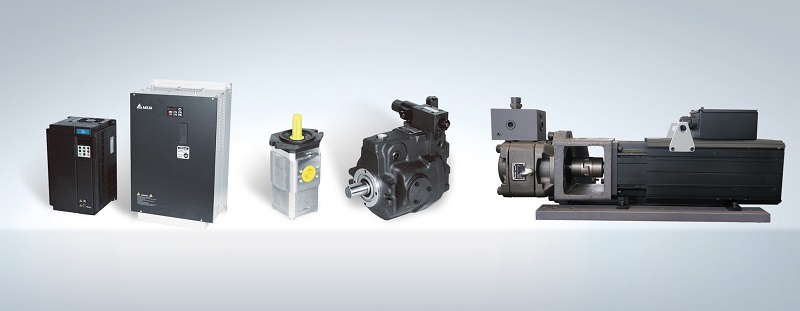

Servo system

Advanced servo energy saving system with small action inertia, low noise, fast response and energy saving

© Copyright: 2025 Lanson Precision Intelligence Equipment Technology Co., Ltd All Rights Reserved.